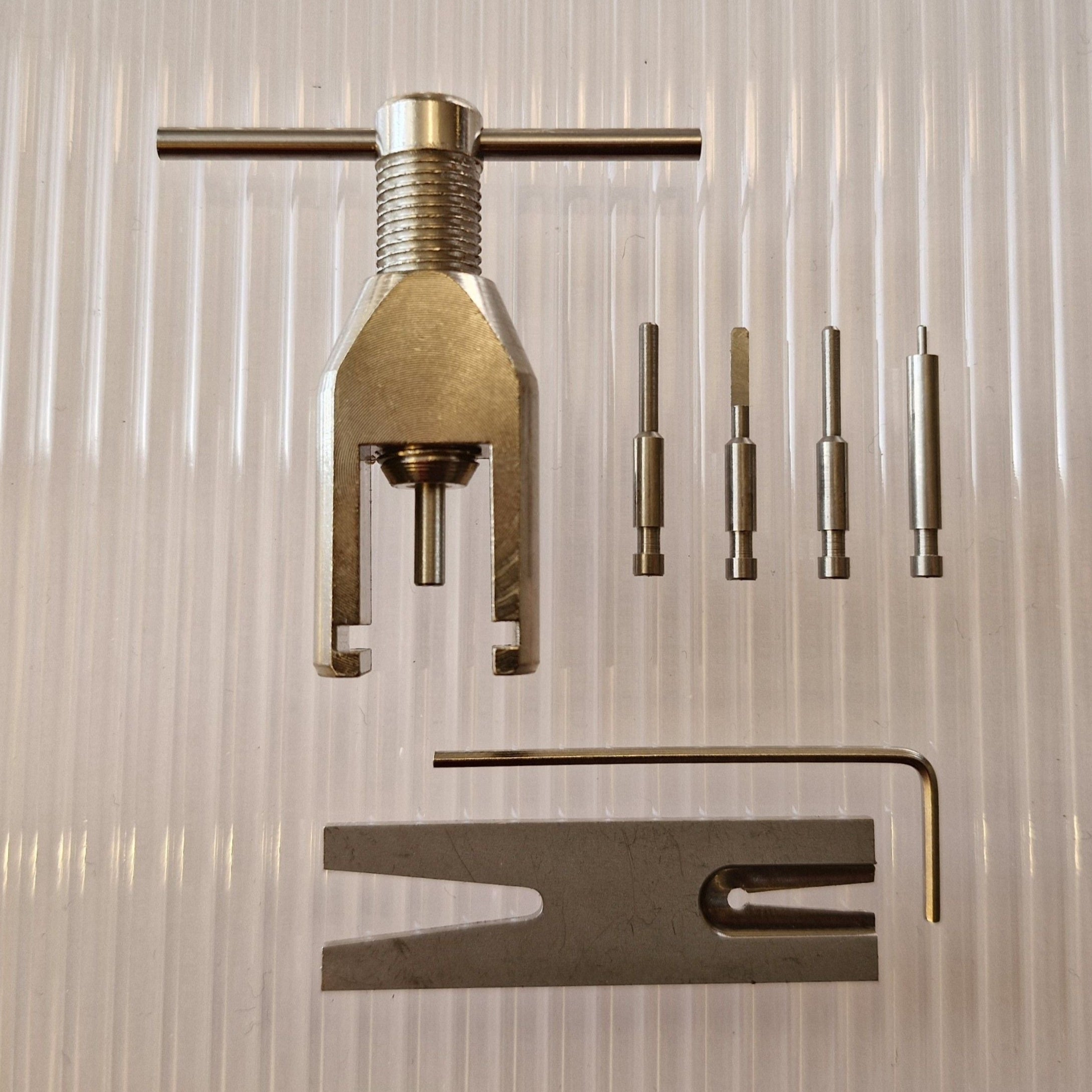

Description

Puller to remove the gear from the electric motor on wheel motors with a 3-4mm shaft.

Sometimes the ball bearings on these motors go bad and create noise, then they can be replaced with this puller and a little work.

It is very easy to damage the gear if you do not use a puller when removing the gear, then this puller makes this job much easier and reduces the risk of failure.

Tip:

Use the largest possible pin for the puller, otherwise it will be bent!

You also have to make some space to get the counterweight under the gear, but once it is in place it is easy to press it away. However, it can be very tight, so a little penetrating oil or heat can be good to use to get the gear to release from the shaft.

Crack the outer bearing race of the ball bearing in a vice to access behind the gear.

On motors with 4mm shaft you have to grind the motor a little to remove the laser welds that fix the bearings to the motor's outer casing. Reassembly is done with loctite.

Fits motors that have gears that are larger than the motor shaft.

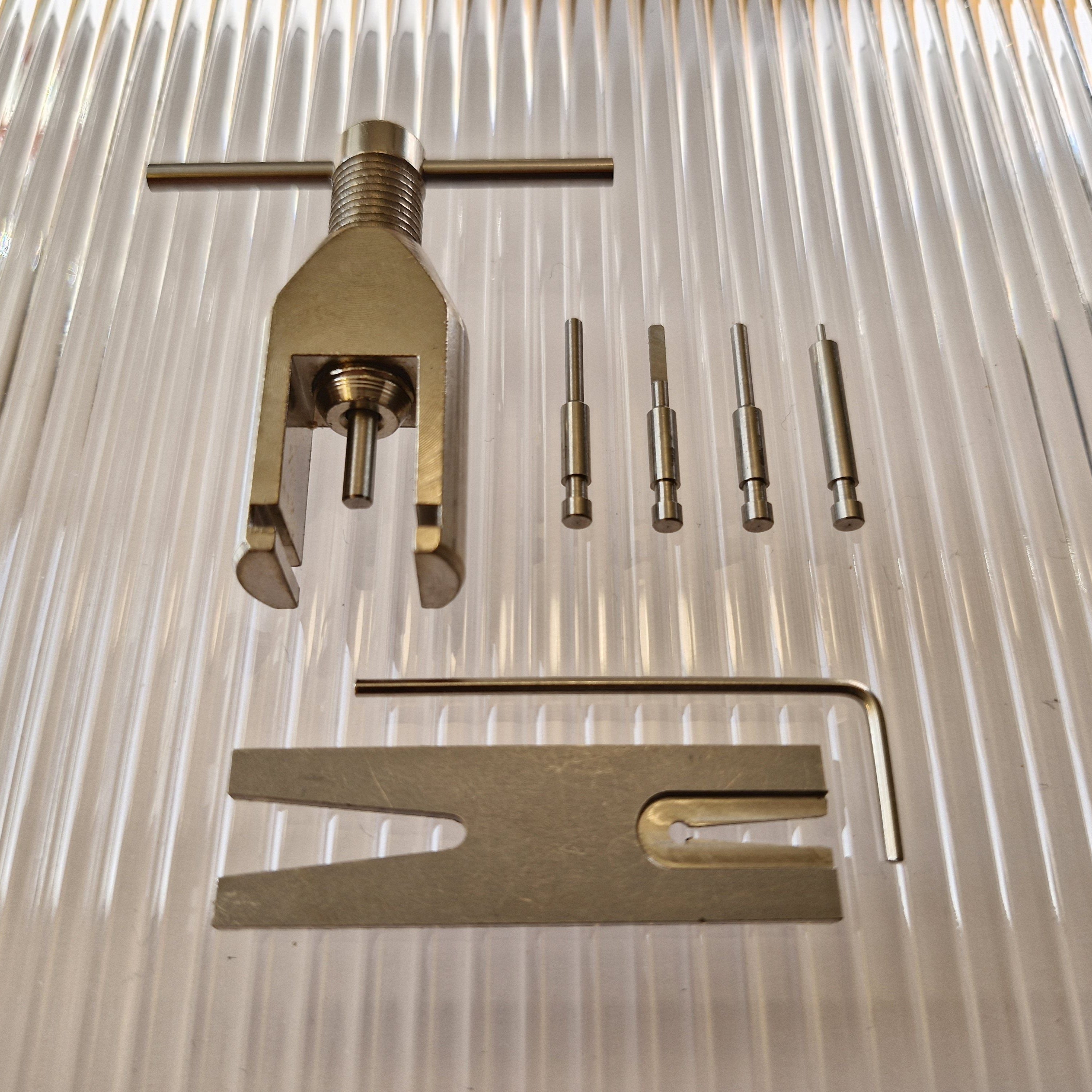

Sometimes the ball bearings on these motors go bad and create noise, then they can be replaced with this puller and a little work.

It is very easy to damage the gear if you do not use a puller when removing the gear, then this puller makes this job much easier and reduces the risk of failure.

Tip:

Use the largest possible pin for the puller, otherwise it will be bent!

You also have to make some space to get the counterweight under the gear, but once it is in place it is easy to press it away. However, it can be very tight, so a little penetrating oil or heat can be good to use to get the gear to release from the shaft.

Crack the outer bearing race of the ball bearing in a vice to access behind the gear.

On motors with 4mm shaft you have to grind the motor a little to remove the laser welds that fix the bearings to the motor's outer casing. Reassembly is done with loctite.

Fits motors that have gears that are larger than the motor shaft.